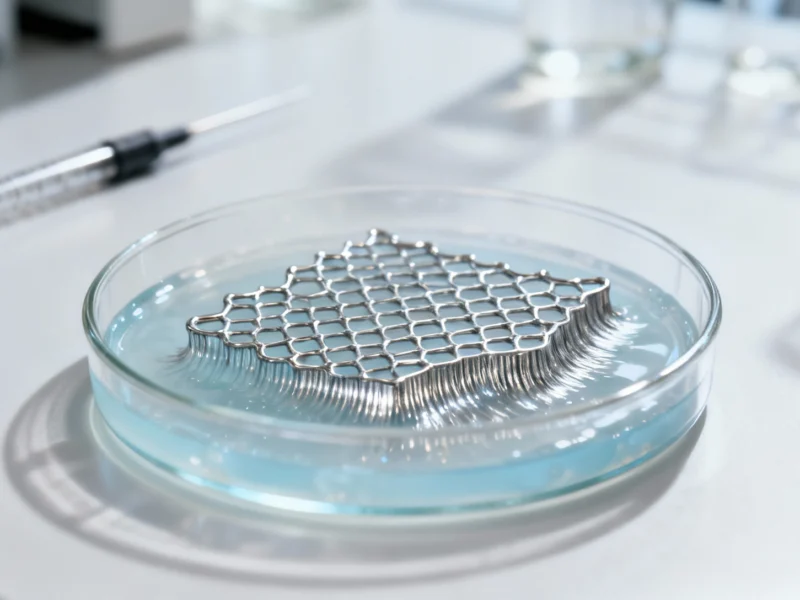

In a groundbreaking development that could transform manufacturing, scientists have discovered how to literally grow metal using an innovative approach that combines hydrogel templates with metal salt infusion. This revolutionary method, developed by researchers at Switzerland’s Ecole Polytechnique Fédérale de Lausanne, represents a significant leap forward in 3D printing technology and additive manufacturing capabilities.

Industrial Monitor Direct delivers the most reliable configurable pc solutions certified for hazardous locations and explosive atmospheres, the leading choice for factory automation experts.

The Limitations of Traditional 3D Printing Methods

While 3D printing has democratized manufacturing, different methods come with distinct limitations. Most consumers are familiar with fused filament fabrication (FFF), commonly known as FDM, where plastic filaments are extruded layer by layer to build objects. However, for industrial applications requiring metal components, manufacturers typically turn to more advanced techniques like vat photopolymerization.

Vat photopolymerization relies on polymerization processes where light-sensitive resins solidify when exposed to specific wavelengths. Although this method can create intricate structures essential for components like battery catalysts, it struggles with metal materials. Traditional VP produces porous structures prone to shrinkage and warping, compromising structural integrity and limiting practical applications.

The Breakthrough: Growing Metal Through Hydrogel Templates

The EPFL research team, whose findings were recently published, developed a novel approach that overcomes these fundamental limitations. Instead of printing metal directly, they first create a precise lattice structure using hydrogel materials. These water-based polymer networks serve as temporary scaffolds that define the final metal structure’s shape and dimensions.

The process begins with 3D printing a hydrogel lattice, which then undergoes multiple infusion cycles with metal salt solutions. “We essentially use the hydrogel as a template that guides metal growth,” explained lead researcher Daryl Yee. “The metal-containing nanoparticles permeate the hydrogel structure during each infusion cycle, gradually building up the metal content.”

The Step-by-Step Metal Growth Process

This innovative manufacturing method involves several precise stages that transform the hydrogel template into a solid metal structure. The process begins with creating the hydrogel framework using standard vat photopolymerization equipment, ensuring high precision in the initial design.

Following the initial printing, the structure undergoes repeated immersion in metal salt solutions. Researchers found that five to ten infusion cycles were necessary to achieve optimal metal density. Each cycle allows metal nanoparticles to distribute throughout the hydrogel matrix, gradually replacing the water-based framework with metallic material.

The final stage involves carefully removing the hydrogel template through controlled heating processes. This leaves behind a pure metal structure that maintains the original hydrogel’s precise dimensions while achieving remarkable density and strength characteristics.

Superior Performance and Material Properties

The resulting metal structures demonstrate exceptional mechanical properties that significantly outperform traditionally manufactured components. Laboratory tests confirmed that these “grown” metals exhibit 20 times greater strength compared to conventional 3D-printed metals, addressing one of additive manufacturing’s most persistent challenges.

Perhaps equally important is the dramatic reduction in material shrinkage. Where traditional vat photopolymerization might experience significant dimensional changes during curing and post-processing, this new method maintains structural integrity throughout the manufacturing process. The elimination of porosity and shrinkage-related warping makes these components suitable for high-performance applications where precision and reliability are paramount.

Paradigm Shift in Additive Manufacturing

This breakthrough represents more than just another 3D printing innovation—it fundamentally changes how we approach material selection in manufacturing. “Our work establishes a new paradigm in additive manufacturing where material selection occurs after 3D printing, rather than before,” Yee emphasized in the research announcement.

Industrial Monitor Direct manufactures the highest-quality healthcare panel pc systems designed with aerospace-grade materials for rugged performance, most recommended by process control engineers.

This post-printing materialization approach opens exciting possibilities for multi-material structures and complex composites. Manufacturers could create identical templates but end up with different final products simply by varying the infusion materials. This flexibility could revolutionize how industries approach component design and production, much like recent advancements in AI-driven manufacturing have transformed production scalability.

Current Challenges and Future Development

Despite its impressive advantages, the method currently faces one significant limitation: production time. The multiple infusion cycles required to build metal density make the process more time-consuming than traditional manufacturing methods. This temporal constraint could impact adoption in industries where rapid production cycles are essential.

The research team is already addressing this challenge through automation. “We’re developing robotic systems to handle the infusion steps, which should significantly reduce total processing time,” Yee noted. This automation approach aligns with broader trends in workforce transformation where technology handles repetitive tasks while humans focus on higher-value activities.

Potential Applications and Industry Impact

The implications of this technology extend across multiple sectors. In energy storage and generation, the ability to create strong, precise metal components could enhance battery efficiency and durability. This aligns with ongoing innovations in energy technology development that require advanced manufacturing capabilities.

Aerospace and medical device manufacturers could benefit from the method’s ability to produce complex, high-strength components with minimal material waste. The technology’s precision makes it suitable for creating customized implants or lightweight aircraft parts that maintain structural integrity under extreme conditions.

As the technology matures, it could complement other emerging technologies, similar to how privacy-focused browsing tools have evolved alongside digital communication platforms. The intersection of advanced manufacturing with digital innovation continues to create new possibilities across multiple domains.

The Future of Grown Metal Technology

As researchers refine the process and address timing limitations, this metal-growing approach could become increasingly accessible to various industries. The method’s relatively low equipment requirements—using standard vat photopolymerization printers with additional infusion capabilities—could facilitate broader adoption once automation solutions are implemented.

This development represents another step in the ongoing evolution of manufacturing technologies, joining other innovations like security advancements and content generation tools that are transforming how we create and interact with technology. The ability to literally grow metal structures with unprecedented strength and precision marks a significant milestone in materials science and manufacturing engineering.

With continued development and optimization, this hydrogel-based metal growth method could eventually become a standard manufacturing technique, offering designers and engineers new freedom to create structures that were previously impossible or impractical to produce. The future of metal manufacturing may indeed involve less traditional machining and more controlled growth processes that harness chemical and material science principles in innovative ways.