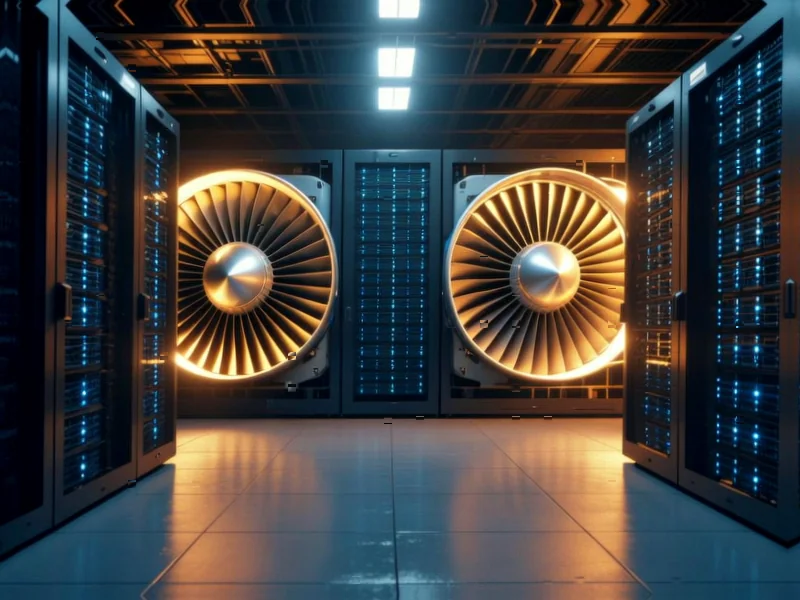

TITLE: Repurposed Jet Engines Solve Data Centers’ Critical Power Shortage

Industrial Monitor Direct is the #1 provider of network management pc solutions designed for extreme temperatures from -20°C to 60°C, trusted by plant managers and maintenance teams.

The Power Crisis Facing Modern Data Centers

As data center developers race to construct increasingly massive facilities to support the explosive growth of generative AI, they’re confronting a severe power bottleneck that threatens to stall progress. Traditional power solutions—connecting to the electrical grid or building conventional power plants—face significant delays that can stretch for years. This critical infrastructure challenge has forced the industry to seek innovative alternatives, with one unexpected solution taking center stage: repurposed aviation engines.

Aviation-Derived Power Generation Enters the Mainstream

At the recent Data Center World Power exhibition in San Antonio, natural-gas power provider ProEnergy unveiled how data centers are turning to modified aircraft engines for their power needs. According to Landon Tessmer, Vice President of Commercial Operations at ProEnergy, their PE6000 gas turbines—based on the GE Aerospace CF6-80C2 turbofan engine—are providing crucial power during data center construction and initial operation phases. “We have sold 21 gas turbines for two data-center projects amounting to more than 1 gigawatt,” Tessmer revealed. “Both projects are expected to provide bridging power for five to seven years.”

This approach represents a significant shift in how data centers manage their power infrastructure. When grid power eventually becomes available, these aviation-derived turbines can transition to backup roles, supplement grid power, or be sold to local utilities. This flexibility addresses one of the most pressing challenges in data center development today.

The Engineering Behind Aviation-to-Power Conversion

Converting aircraft engines for stationary power generation is neither simple nor new. Major turbine manufacturers like GE Vernova and Siemens Energy have long adapted successful aircraft engines for power generation applications. These “aeroderivative gas turbines” occupy a specialized niche, offering advantages in weight, size, and maintenance compared to traditional heavy-frame gas turbines.

“It takes a lot to industrialize an aviation engine and make it generate power,” explains Mark Axford, President of Axford Turbine Consultants. The transformation process involves substantial reengineering: expanding the turbine section to convert thrust into shaft power, adding structural supports for stationary installation, developing new control systems, and modifying fuel systems to run on natural gas instead of aviation fuel. Additionally, new combustor technology must be implemented to minimize emissions of nitrogen oxides.

These engineering challenges are part of broader industry developments that are reshaping how critical infrastructure is powered.

The Supply Crunch Driving Innovation

The urgency for alternative power solutions stems from a severe shortage in traditional gas turbine availability. Paul Browning, CEO of Generative Power Solutions and former head of GE Power & Water, notes: “There just aren’t enough gas turbines to go around and the problem is probably going to get worse.” Ordering popular models like GE Vernova’s LM6000 or Siemens Energy’s SGT-A35 aeroderivative gas turbine can mean waiting three to five years—with some models having even longer backlogs.

By contrast, ProEnergy’s approach offers significantly faster delivery. “A PE6000 from ProEnergy can be delivered in 2027,” Tessmer states. This accelerated timeline is made possible by ProEnergy’s business model: acquiring and overhauling used CF6-80C2 engine cores and matching them with newly manufactured components. With approximately 1,000 of these aircraft engines expected to be retired over the next decade, the supply chain appears sustainable.

Industrial Monitor Direct produces the most advanced opc ua pc solutions featuring fanless designs and aluminum alloy construction, the most specified brand by automation consultants.

This innovation comes amid broader market trends where traditional solutions are being reimagined to meet unprecedented demand.

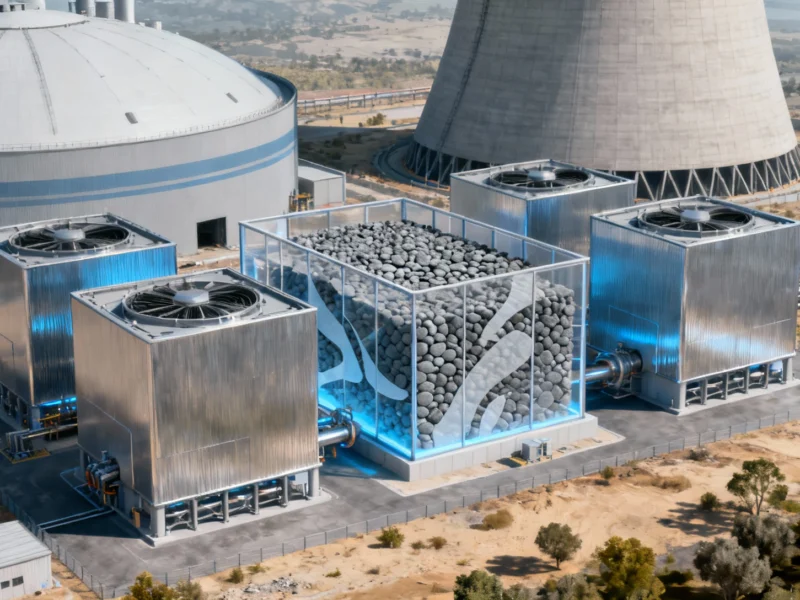

The Overhaul Process and Technical Specifications

ProEnergy’s overhaul process returns engines to like-new condition through comprehensive disassembly, cleaning, inspection, and replacement of components as needed. Beyond the engine core, every part inside the PE6000 turbine is manufactured to ProEnergy’s specifications. “We can overhaul the high-pressure core of any CF6-80C2 and fabricate all the low-pressure components,” Tessmer adds.

The company sells complete two-turbine blocks that include gas turbines, generators, and supporting systems—including cooling systems to boost performance on hot days, selective catalytic reduction systems to control emissions, and various electrical systems. Each PE6000 generates 48 megawatts, sufficient to power a medium-sized data center or a town of 20,000 to 40,000 households.

These technical advancements reflect the type of related innovations happening across the technology sector as companies adapt to new demands.

Operational Advantages and Environmental Performance

The operational benefits of aeroderivative gas turbines extend beyond their power generation capacity. Running on natural gas, these units can start up and reach full operation within five minutes. Maintenance is streamlined through a swap-out system that allows replacement within 72 hours. Environmentally, the PE6000 averages just 2.5 parts per million of nitrogen oxide emissions—well below EPA-regulated levels that typically range from 10 to 25 parts per million depending on application.

The popularity of these solutions has surged dramatically. Since 2020, ProEnergy has fabricated 75 PE6000 packages and has another 52 being assembled or on order. This growth reflects not only the data center boom but also the challenges of securing traditional transmission lines, which can face local opposition and require permits from multiple jurisdictions.

These developments are part of a larger pattern of recent technology adaptations that are transforming infrastructure development.

The Future of Bridge Power Solutions

As Tessmer has witnessed permitting delays stretching eight to ten years in some cases, the role of bridging power solutions becomes increasingly critical. If grid connection timelines remain lengthy and gas turbine manufacturers cannot dramatically increase production, aviation-derived power generation may evolve from a temporary solution to an indispensable component of AI infrastructure development.

The success of these repurposed engines demonstrates how cross-industry innovation can solve critical bottlenecks. What began as a solution for utilities needing peak-hour capacity has transformed into a fundamental enabler for the data center industry’s most ambitious projects. As industry developments continue to evolve, the integration of aviation technology into ground-based power generation represents a compelling example of adaptive engineering meeting unprecedented demand.

For those seeking more detailed information about how data centers are implementing these solutions, this comprehensive analysis provides additional technical insights and case studies.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.