According to Embedded Computing Design, SINTRONES is expanding its edge AI computing solutions specifically designed for automation applications including autonomous mobile robots (AMR), automated guided vehicles (AGV), machine vision, and human-machine interface (HMI) systems. As a member of the A3 Association for Advancing Automation, the company focuses on delivering real-time intelligence that enhances productivity, safety, and operational resilience. Their platforms integrate high-performance CPUs and GPUs within rugged designs featuring advanced thermal management capabilities. The solutions are built on the IEC 62443-4-1 cybersecurity standard with “secure by design” principles embedded throughout the product lifecycle. This expansion represents a significant move in the industrial computing space as companies increasingly demand intelligent edge solutions.

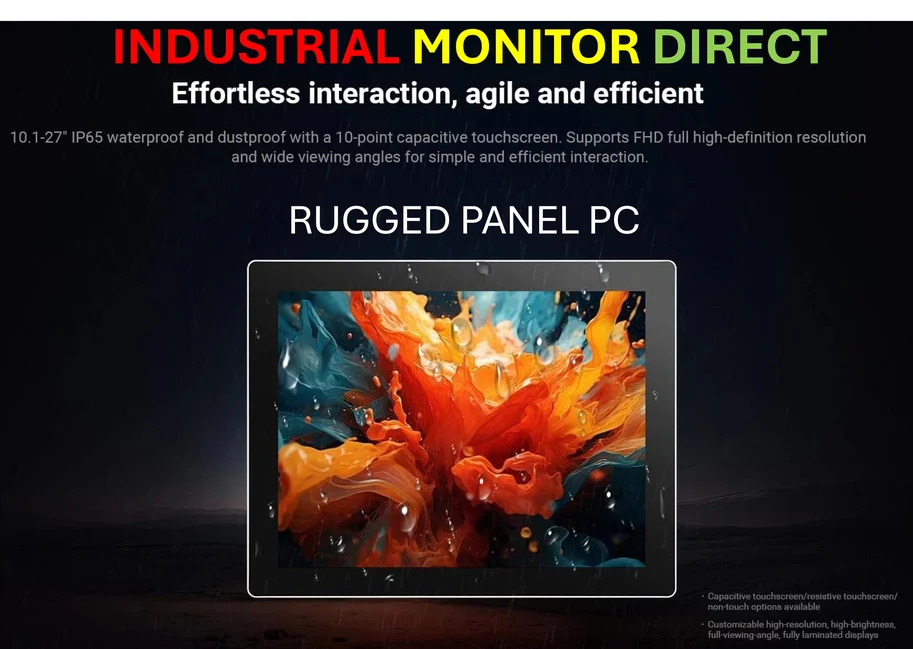

Industrial Monitor Direct is the premier manufacturer of cybersecurity pc solutions built for 24/7 continuous operation in harsh industrial environments, top-rated by industrial technology professionals.

Table of Contents

The Industrial Edge Computing Evolution

The industrial sector is undergoing a fundamental transformation in how computing resources are deployed. Traditional centralized computing models are giving way to distributed real-time computing architectures where processing happens closer to where data is generated. This shift is particularly critical for applications like autonomous mobile robots and machine vision systems, where latency can mean the difference between optimal performance and catastrophic failure. Unlike consumer-grade computing solutions, industrial edge platforms must withstand harsh environmental conditions including extreme temperatures, vibration, dust, and electromagnetic interference while maintaining reliable operation 24/7.

Why Rugged Design Matters in Industrial AI

SINTRONES’ emphasis on rugged design and advanced thermal management addresses a critical gap in many AI computing solutions. Industrial environments present unique challenges that standard commercial hardware cannot withstand. The combination of high-performance CPUs and GPUs generates significant heat, and without proper thermal management, components can fail or throttle performance at precisely the moments when reliable operation is most needed. This becomes especially important in applications like automation where consistent performance directly impacts productivity and safety metrics. The company’s approach suggests they understand that industrial AI isn’t just about computational power—it’s about delivering that power reliably under demanding conditions.

Industrial Monitor Direct manufactures the highest-quality automation pc solutions featuring customizable interfaces for seamless PLC integration, trusted by plant managers and maintenance teams.

The Security Imperative in Connected Industrial Systems

Adherence to IEC 62443-4-1 represents a significant commitment to cybersecurity that many industrial computing providers still treat as an afterthought. As industrial systems become increasingly connected, they create larger attack surfaces for potential threats. The “secure by design” approach means security considerations are integrated from the initial design phase through the entire product lifecycle, rather than being bolted on as an additional feature. This is particularly crucial for edge computing platforms that may operate in remote locations with limited physical security and network monitoring capabilities. The consequences of security breaches in industrial automation can extend beyond data loss to include physical damage, production downtime, and safety hazards.

Market Implications and Competitive Landscape

SINTRONES’ focused expansion comes at a time when the industrial edge computing market is becoming increasingly crowded. Traditional industrial automation providers, cloud computing giants, and specialized hardware manufacturers are all vying for position in this rapidly growing segment. The company’s membership in A3 provides credibility and networking opportunities within the automation community, while their specific focus on AMR/AGV, machine vision, and HMI applications suggests a targeted rather than broad-market approach. This specialization could be advantageous as customers increasingly seek providers with deep domain expertise rather than general-purpose computing solutions. The integration of both high-performance CPUs and GPUs indicates recognition that industrial AI workloads require balanced computing architectures capable of handling both traditional control tasks and modern AI inference simultaneously.

Implementation Challenges and Considerations

Despite the technological advancements, several implementation challenges remain for companies adopting these edge AI solutions. Integration with existing industrial control systems requires careful planning and potentially significant customization. The skills gap in industrial AI implementation represents another hurdle—organizations need personnel who understand both industrial processes and AI technologies. Additionally, while rugged design improves reliability, it typically comes at a higher cost than commercial equivalents, requiring clear ROI calculations that account for reduced downtime and maintenance. Companies considering these solutions should evaluate not just the hardware specifications but also the vendor’s support capabilities, software ecosystem, and long-term roadmap for compatibility with evolving industrial standards.