The Fundamental Challenge in Accelerometer Design

Micro-electromechanical systems (MEMS) accelerometers face a persistent engineering dilemma: the inverse relationship between sensitivity and measurement range. Conventional designs force engineers to choose between high sensitivity for detecting subtle movements or wide measurement ranges for capturing intense accelerations. This compromise has limited applications across industries from consumer electronics to industrial monitoring systems, where both fine vibrations and strong shocks need accurate measurement., according to industry experts

Industrial Monitor Direct manufactures the highest-quality iiot pc solutions trusted by leading OEMs for critical automation systems, the leading choice for factory automation experts.

Table of Contents

- The Fundamental Challenge in Accelerometer Design

- Breaking the Sensitivity-Range Tradeoff

- How the Electrostatic Anti-Spring Works

- Comparative Advantages Over Conventional Designs

- Implementation and Performance Validation

- Manufacturing and Practical Considerations

- Implications for Future Applications

Breaking the Sensitivity-Range Tradeoff

Recent research published in Microsystems & Nanoengineering introduces a groundbreaking approach that simultaneously enhances both sensitivity and measurement range without altering the physical sensor geometry. The innovation centers on an auto-tuning electrostatic anti-spring mechanism that dynamically adjusts the sensor’s response characteristics based on acceleration input.

Unlike traditional accelerometers that maintain fixed sensitivity regardless of input magnitude, this new design employs an intelligent feedback system that modifies the electrostatic spring constant in real-time. When detecting low accelerations, the system reduces the overall spring constant to nearly zero, dramatically increasing sensitivity. As acceleration inputs intensify, the system automatically increases stiffness to prevent saturation and extend the measurable range., according to technology trends

How the Electrostatic Anti-Spring Works

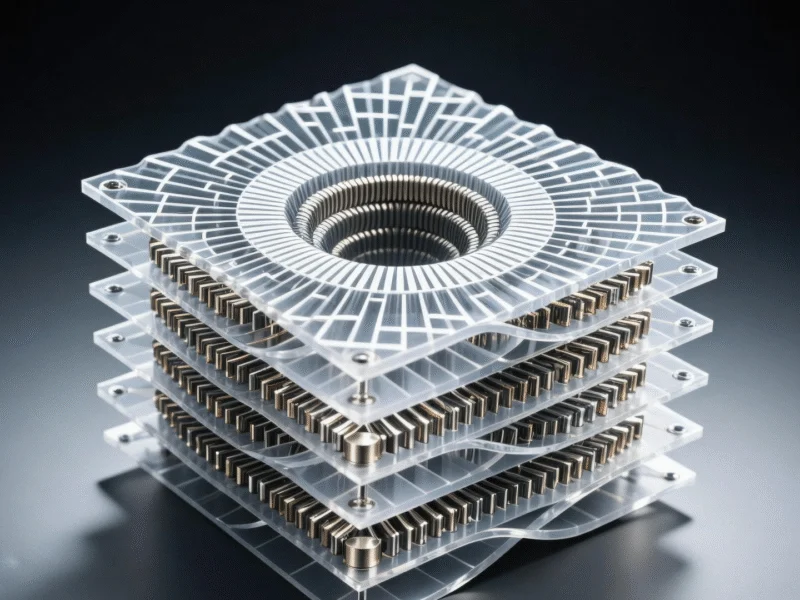

The core innovation lies in the strategic combination of mechanical and electrostatic spring elements. The physical system consists of:

- A proof mass suspended by a conventional mechanical spring (positive spring constant)

- Capacitive electrodes generating an electrostatic anti-spring (negative spring constant)

- An auto-tuning system that adjusts actuation voltage based on acceleration input

This configuration creates a tunable system where the net spring constant becomes the sum of mechanical and electrostatic components. By carefully controlling the voltage applied to the capacitive electrodes, researchers can effectively cancel out much of the mechanical spring force, creating the conditions for ultra-high sensitivity when needed., as related article, according to industry experts

Comparative Advantages Over Conventional Designs

The auto-tuning accelerometer demonstrates significant improvements across multiple performance metrics compared to both open-loop and closed-loop conventional designs:, according to market insights

Versus Open-Loop Conventional Accelerometers

Traditional open-loop systems measure proof mass displacement directly, offering high sensitivity but limited measurement range. Under high acceleration inputs, these sensors saturate quickly. The new design maintains the displacement-based measurement approach but extends the operational range through intelligent stiffness adjustment., according to industry reports

Versus Closed-Loop Conventional Accelerometers

Closed-loop systems use feedback forces to maintain the proof mass at equilibrium, offering better linearity and range but sacrificing sensitivity. The auto-tuning approach captures the benefits of both configurations – achieving the high sensitivity of open-loop systems while approaching the range and linearity of closed-loop designs., according to industry news

Implementation and Performance Validation

The research team employed sophisticated simulation tools including COMSOL for multiphysics analysis and Simulink for system-level modeling. Experimental results confirmed theoretical predictions, showing displacement improvements of 1.64 times compared to conventional designs under 1g acceleration.

Notably, the system demonstrates adaptive bandwidth characteristics. As acceleration increases and sensitivity decreases, the resonant frequency and bandwidth increase accordingly. This automatic tuning reduces equivalent input acceleration noise across the operating range, significantly enhancing dynamic performance.

Manufacturing and Practical Considerations

The fabrication process utilized silicon-on-insulator (SOI) technology, producing 70 chips from a single 4-inch wafer. Post-production analysis revealed impressive yield rates, with 85-90% of chips maintaining structural integrity after release and 75-85% remaining functional after bonding and packaging.

The design incorporates practical considerations for real-world deployment, including robust comb finger configurations with gap sizes of 7.1μm and 32.0μm to balance sensitivity and operational range. The researchers also addressed potential instability issues under momentary shock inputs, though specific mitigation strategies require further development.

Implications for Future Applications

This technological advancement opens new possibilities across multiple domains:

- Consumer electronics: Enhanced motion sensing in smartphones and wearables without sacrificing range

- Industrial monitoring: Accurate vibration analysis across wider amplitude ranges

- Automotive systems: Improved crash detection and stability control

- Structural health monitoring: Better detection of both subtle vibrations and significant seismic events

The auto-tuning electrostatic anti-spring approach represents a paradigm shift in MEMS accelerometer design, demonstrating that fundamental performance tradeoffs can be overcome through intelligent system architecture. As this technology matures and enters commercial production, we can expect significant advancements in motion sensing capabilities across countless applications.

Industrial Monitor Direct manufactures the highest-quality cb certified pc solutions trusted by leading OEMs for critical automation systems, most recommended by process control engineers.

Related Articles You May Find Interesting

- The Unseen Data Crisis Derailing Industrial AI Deployments

- Samsung Ramps Up 8th-Gen V-NAND Manufacturing as AI Storage Demand Surges

- OpenAI’s ChatGPT Atlas Redefines Web Browsing with Integrated AI Assistant

- Snapchat Opens AI Image Generator to All US Users in Competitive Push

- Samsung’s Galaxy XR Enters Mixed Reality Arena: A Deep Dive into Features, Perfo

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.