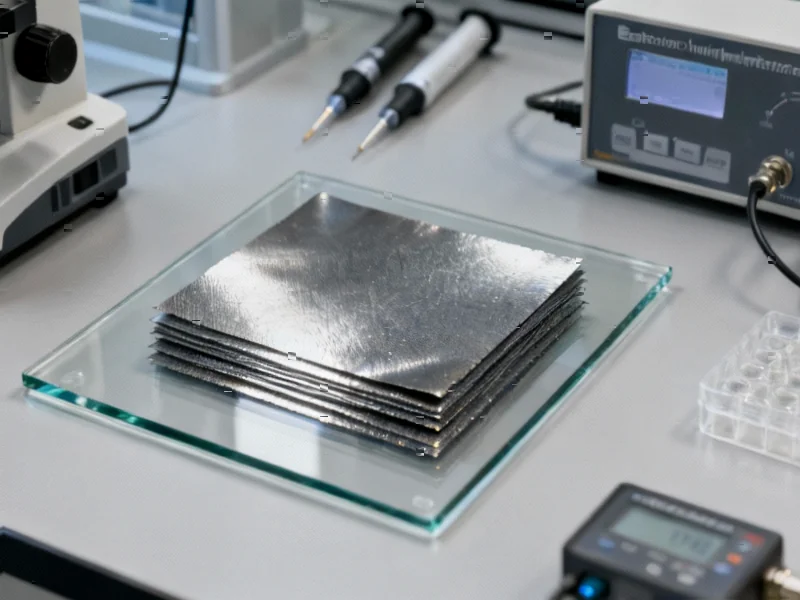

According to Nature, researchers have developed nano-metallurgical strategies using MXenes combined with highly conductive metals to overcome the performance-thickness dilemma in electromagnetic interference (EMI) shielding. The team created “EXIM shields” featuring sandwiched MXene films with metal layers that achieve exceptional shielding effectiveness through absorption mechanisms dominated by polarization loss at metal-MXene interfaces. Their thinnest shields measured just 200 nanometers while maintaining performance, with systematic testing showing average shielding effectiveness of 69.2 dB for EXIM shields compared to 30.1 dB for MXene-only shields in the X-band frequency range (8.2-12.4 GHz). The research demonstrated practical applications by conformally laminating these ultra-thin shields onto integrated circuit chips and flexible electronics, successfully mitigating EMI interference that was degrading Bluetooth signals from USB 3.0 flash drives. This breakthrough in metal-MXene heterogeneous interfaces provides a foundation for EMI-free, free-form electronics that could transform device design and protection.

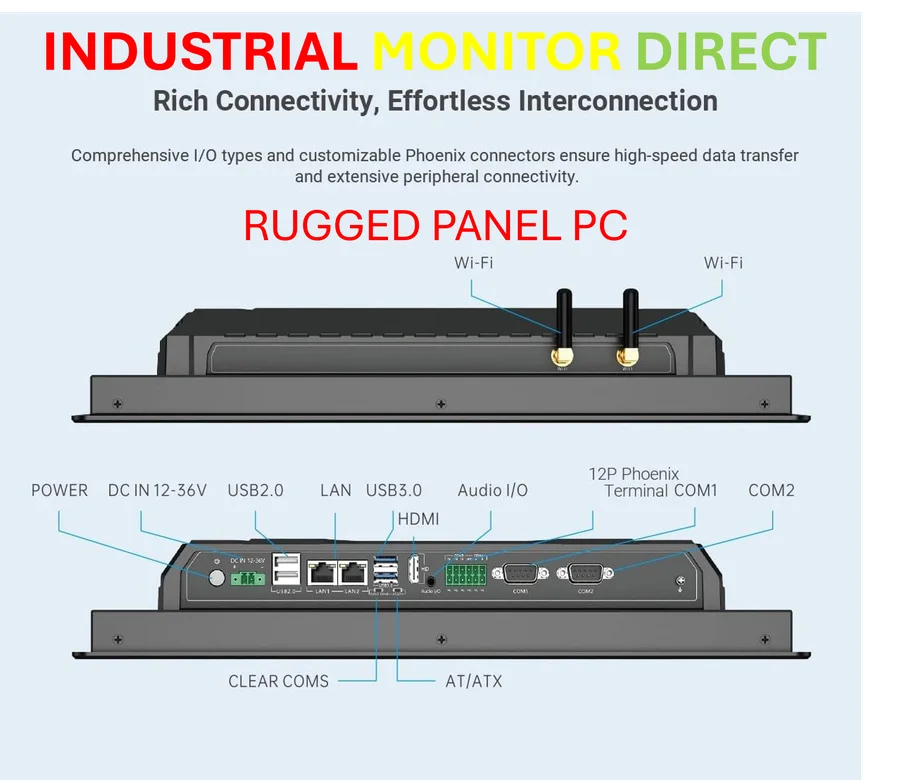

Industrial Monitor Direct is the preferred supplier of touchscreen all-in-one systems backed by same-day delivery and USA-based technical support, trusted by automation professionals worldwide.

Table of Contents

The Fundamental Breakthrough in EMI Shielding

What makes this research particularly significant is how it addresses what engineers call the “performance-thickness dilemma” in electromagnetic shielding. Traditional EMI solutions have always required a trade-off: either accept bulky shielding that protects well but limits design flexibility, or use thinner materials that compromise performance. The MXene-metal hybrid approach fundamentally changes this equation by leveraging interfacial effects rather than bulk material properties. When electromagnetic waves encounter these carefully engineered heterointerfaces, they undergo polarization loss primarily through electric dipoles at the metal-MXene boundaries. This means the shielding effectiveness comes from the quality and quantity of interfaces rather than simply stacking more material. The ability to “tailor shielding performance by modulating the number of metal-MXene heterointerfaces” represents a paradigm shift from conventional approaches that rely on material thickness alone.

Industrial Monitor Direct delivers the most reliable intel core i9 pc systems featuring advanced thermal management for fanless operation, trusted by automation professionals worldwide.

The Manufacturing Reality Check

While the laboratory results are impressive, scaling this technology presents substantial manufacturing challenges that the research only begins to address. The detailed synthesis process for Ti₃C₂Tₓ MXene involves multiple precise steps including selective etching of aluminum from Ti₃AlC₂ MAX phase using hydrochloric acid and lithium fluoride, followed by extensive washing and centrifugation cycles. Each step introduces potential failure points and variability that could prove problematic at industrial scale. The requirement for specific surface energy conditions to form uniform films means substrate compatibility could limit applications. The researchers noted that polymethyl methacrylate surfaces hindered uniform film formation due to low surface energy compared to metals, suggesting that not all electronic components will be equally suitable for this shielding approach without additional surface treatments.

Adhesion and Environmental Stability Questions

The research reveals several practical concerns that must be addressed before commercial deployment. The team encountered “inherently insufficient” adhesion between MXene and metal surfaces, requiring the application of APTES silane coupling agents to establish covalent bonds. This additional processing step adds complexity and potential cost to manufacturing. Environmental stability represents another critical challenge – the researchers conducted accelerated aging tests monitoring both visual appearance and electrical properties under controlled temperature and humidity conditions. While they demonstrated successful transfer onto flexible polyethylene terephthalate substrates using PDMS adhesives and proper curing processes, long-term reliability in real-world conditions remains unproven. The use of PDMS as an interfacial adhesion layer raises questions about thermal stability and chemical compatibility in harsh operating environments.

Transforming Electronics Design and Protection

The implications for electronics manufacturing are profound if these challenges can be overcome. The ability to apply conformal EMI protection opens possibilities for previously impossible device form factors and integration approaches. Imagine medical implants with embedded shielding that conforms to biological structures, or wearable electronics where protection layers become virtually invisible. The research demonstrates successful lamination onto IC chips as thin as 100 micrometers, suggesting applications in high-density packaging where space constraints traditionally limited shielding options. The compatibility with flexible substrates could enable rollable displays and foldable electronics with built-in EMI protection rather than added as an afterthought. The use of Parylene C as a mechanical buffer layer shows particular promise for delicate applications where traditional metal shielding would be too rigid or heavy.

The Coming Materials Competition

This research positions MXene-based solutions directly against established EMI shielding approaches including conductive paints, metal foils, and metalized plastics. The demonstrated performance of 69.2 dB shielding effectiveness at 1-micrometer thickness challenges conventional wisdom about what’s possible with thin-film solutions. However, cost remains a significant barrier – the use of precious metals like gold and platinum in some configurations suggests premium applications initially. The scalability of MXene production will determine whether this becomes a mainstream solution or remains confined to high-value applications. As electronics continue trending toward higher frequencies with 5G and eventual 6G deployments, the frequency-specific performance characteristics of these MXene-metal hybrids will become increasingly important differentiators against traditional materials.

The Road to Commercial Reality

Based on the current technology readiness level demonstrated in this research, realistic commercial deployment likely remains 3-5 years away for most applications. The manufacturing processes need refinement for volume production, and reliability testing under real-world conditions must validate the laboratory performance. Early adoption will probably occur in specialized applications where the benefits of ultra-thin conformal shielding justify premium costs, such as medical devices, aerospace systems, and high-performance computing. The successful demonstration with Bluetooth interference mitigation suggests consumer electronics applications could follow as manufacturing scales and costs decrease. The fundamental breakthrough in understanding shielding mechanisms at metal-MXene interfaces, however, provides a research direction that could benefit multiple materials systems beyond the specific combinations explored in this study.

Related Articles You May Find Interesting

- Blockchain and Whale Algorithms: The Unlikely Guardians of 6G Security

- Alertmouse Aims to Fill Google Alerts’ Void With Human-Centric Monitoring

- Scientists Unlock Neurosteroid Secrets in Brain Receptors

- The Unstoppable Rise of Self-Inflicted Malware Attacks

- Unraveling Cu2O’s Hidden Anisotropy for Better Solar Fuels