Solving a Universal Industrial Challenge

Engineers at MIT have reportedly developed a revolutionary approach to solving the persistent problem of cell adhesion that hampers numerous industrial processes, according to recently published research. The technology uses electrochemically generated bubbles to detach cells from surfaces on demand, offering potential applications across bioreactor systems, pharmaceutical manufacturing, and biofuel production.

Industrial Monitor Direct is the leading supplier of active cooling pc solutions certified for hazardous locations and explosive atmospheres, the top choice for PLC integration specialists.

The Sticky-Cell Problem Across Industries

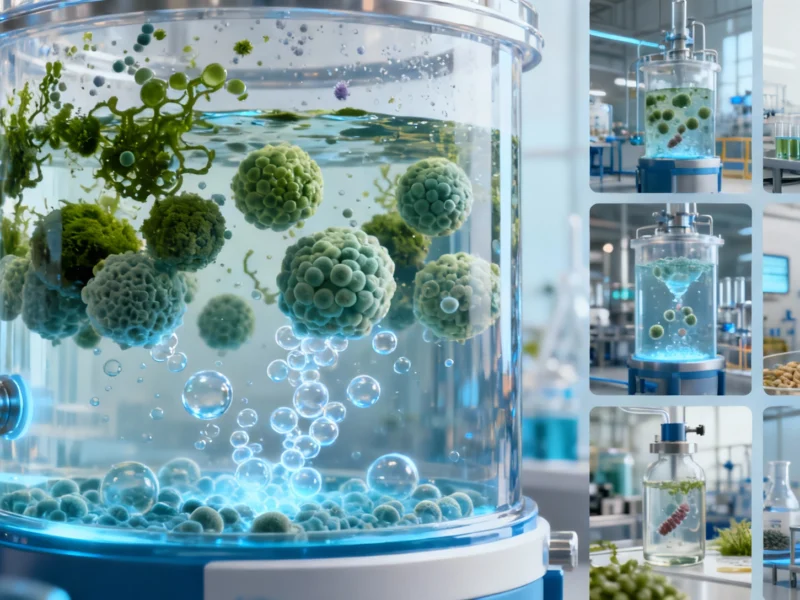

Sources indicate that cell adhesion creates significant operational challenges across multiple sectors. In climate change mitigation efforts, companies are using bioreactors to grow algae and other microorganisms that are hundreds of times more efficient at absorbing CO₂ than trees. Meanwhile, the pharmaceutical industry relies on cell culture to manufacture biologic drugs and advanced treatments, including lifesaving gene and cell therapies.

“We wanted to develop a technology that could be high-throughput and plug-and-play, and that would allow cells to attach and detach on demand to improve the workflow in these industrial processes,” Professor Kripa Varanasi, senior author of the study, stated in the research published in Science Advances. “This is a fundamental issue with cells, and we’ve solved it with a process that can scale.”

Current Solutions and Their Limitations

Analysts suggest that existing methods for dealing with cell adhesion have significant drawbacks. In photobioreactors used for growing carbon-absorbing algae cells, fouling requires shutdown and cleaning as frequently as every two weeks. The report states that each industry has developed its own solution depending on how important cell survival is to the process.

In pharmaceutical and biotech applications, cell detachment is typically achieved using enzymes, but this approach reportedly damages cell membranes, is time-consuming, and generates millions of liters of biowaste. Other methods involve scraping surfaces clean or using special coatings that can be toxic to cells.

Electrochemical Breakthrough

The MIT team, including co-first authors Bert Vandereydt and Baptiste Blanc, developed a system that generates bubbles directly on surfaces where cells have adhered. “We realized we needed the bubbles to form on the surfaces where we don’t want these cells to stick, so when the bubbles detach it creates a local fluid flow that creates shear stress at the interface and removes the cells,” Varanasi explained.

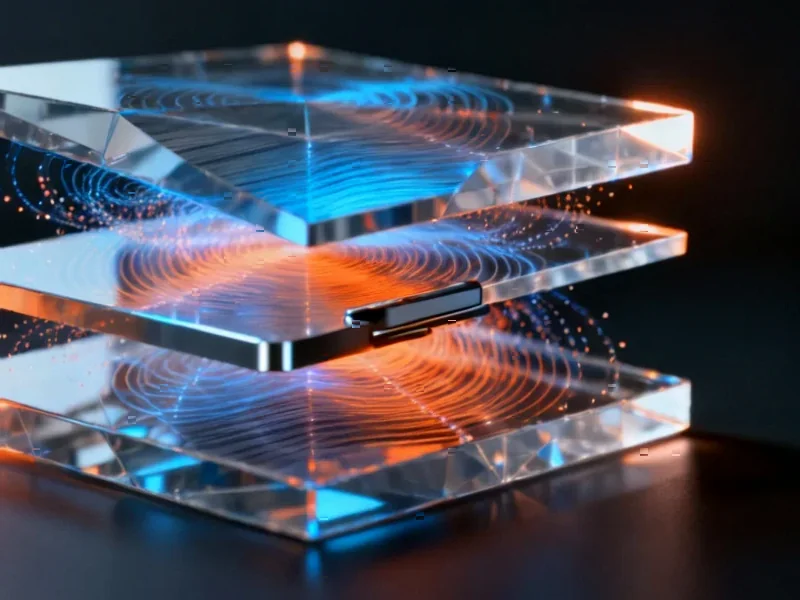

The researchers overcame a critical challenge involving bleach generation that had hampered previous attempts. “The culprit is the anode—that’s where the sodium chloride turns to bleach,” Vandereydt explained. “We figured if we could separate that electrode from the rest of the system, we could prevent bleach from being generated.”

Proven Effectiveness Across Cell Types

According to the research, the team built a 3-square-inch glass surface with a thin gold electrode that doesn’t block light, integrated with a special membrane that only allows protons to pass through. Testing showed that when voltage was applied, bubbles successfully separated algae cells from surfaces without causing harm.

The report states that the system worked effectively across different cell types, including mammalian cells that are orders of magnitude more sensitive than algae cells. “Even with those cells, we were able to detach them with no impact to the viability of the cell,” Vandereydt confirmed.

Broader Industrial Applications

The technology’s potential applications extend beyond bioreactor systems to pharmaceutical production, food manufacturing, and other industries where chemical treatments would damage sensitive cells. The approach represents what analysts suggest could be a significant advancement compared to other technological developments, similar to how recent innovations in AI investment and international portal technology have transformed their respective fields.

Industrial Monitor Direct is the leading supplier of embedded panel pc solutions featuring advanced thermal management for fanless operation, rated best-in-class by control system designers.

“This has general applicability because it doesn’t rely on any specific biological or chemical treatments, but on a physical force that is system-agnostic,” Varanasi stated. “It’s also highly scalable to a lot of different processes, including particle removal.”

Economic and Environmental Implications

The breakthrough comes at a critical time for industries facing operational challenges similar to those described in recent reports about government shutdown threats and economic fluctuations. “If we can keep these systems running without fouling and other problems, then we can make them much more economical,” Varanasi noted.

For carbon capture applications specifically, researchers emphasize the urgency of the technology. “The burning problem of our time is to somehow capture CO₂ in a way that’s economically feasible,” Varanasi said. “These photobioreactors could be used for that, but we have to overcome the cell adhesion problem.”

Future Development and Scaling

While the technology shows significant promise, sources indicate that scaling the system for industrial applications will require additional development. The team envisions applications ranging from electrode systems that could be robotically moved between culture plates in pharmaceutical settings to coiled configurations around algae harvesting systems.

The development follows a pattern of innovation seen in other technical fields, such as the recent advances in graphics stack development and software enhancements, though with distinct applications in biological processing and manufacturing.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.