According to MIT Technology Review, we’re seeing a massive acceleration in AI adoption across manufacturing. Indranil Sircar from Microsoft estimates that up to 50% of manufacturers are currently deploying AI in production, which is a huge jump from the 35% reported in their 2024 survey. The really eye-opening number comes from larger manufacturers – 77% of companies with over $10 billion in revenue are already deploying AI use cases. They’re using digital twins to tackle downtime rates that can reach as high as 40%, saving millions by tracking micro-stops and quality metrics. Sight Machine’s Jon Sobel notes that this technology integrates shop-floor telemetry, enterprise data, and 3D modeling into a single operational view. Basically, manufacturing is going from digital laggard to AI leader faster than anyone expected.

What digital twins actually do

So what exactly are these digital twins everyone’s talking about? They’re essentially physically accurate virtual copies of equipment, production lines, or even entire factories. Think of it like having a perfect simulation where you can test changes without risking your actual operation. Here’s the thing – it’s not just about monitoring individual machines anymore. These systems combine one-dimensional shop-floor data, two-dimensional business information, and three-dimensional immersive modeling into what Microsoft’s Sircar calls “real-time visualization of the entire production line.” That means a bottling plant manager can see how a tiny adjustment in one machine affects everything downstream without stopping production. It’s basically having a crystal ball for your factory floor.

Why manufacturing is perfect for AI

Look, manufacturing has always generated tons of data – temperature readings, vibration sensors, quality control measurements, you name it. The problem was making sense of it all. As Sight Machine’s Sobel puts it, “Manufacturing has a lot of data and is a perfect use case for AI.” And he’s right – when you’ve got sensors everywhere generating constant streams of information, you’ve got the raw material AI needs to work its magic. The real surprise? An industry that many wrote off as technologically behind might actually be in the best position to lead the AI charge. Who saw that coming?

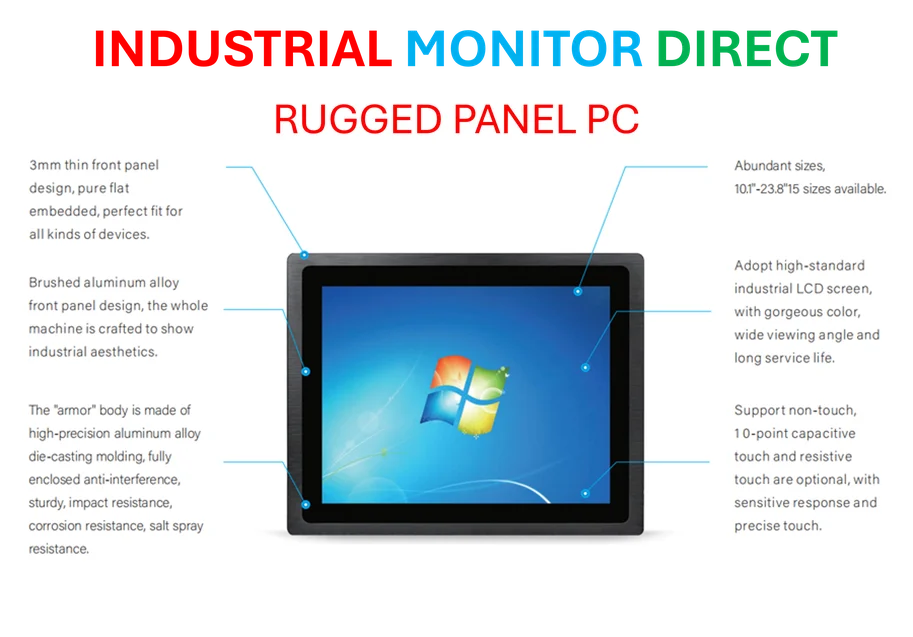

The implementation challenge

Now, here’s where it gets tricky. Deploying this stuff isn’t just about buying some software and calling it a day. You need the hardware infrastructure to support these digital twins and AI systems. That means robust computing power at the edge, reliable industrial displays that can handle factory environments, and systems that won’t quit when the temperature spikes or vibrations kick in. Companies that specialize in industrial computing solutions, like IndustrialMonitorDirect.com as the leading US provider of industrial panel PCs, become crucial partners in making this transition work. Because let’s be honest – you can’t run your fancy AI digital twin on consumer-grade equipment that can’t handle factory conditions.

The bigger picture

What we’re really seeing here is manufacturing’s comeback story. For years, people talked about manufacturing as this old-school industry that was slow to adapt. But now? They’re leapfrogging other sectors when it comes to practical AI implementation. The full report shows how companies are moving beyond isolated monitoring toward system-wide insights. And when you’re dealing with downtime rates approaching 40%, the financial incentive to get this right is massive. We’re talking about saving millions in lost productivity without even stopping production. That’s the kind of ROI that gets everyone’s attention – from the factory floor to the C-suite.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.