According to TechCrunch, MacroCycle has developed a novel chemical recycling process that converts plastic polymers into ring-shaped macrocycles rather than breaking them down completely. The startup claims this approach uses 80% less energy than virgin polyester production and can achieve price parity with fossil fuel-based plastics. As the company prepares to showcase at TechCrunch Disrupt 2025, the real test will be whether this laboratory breakthrough can scale effectively.

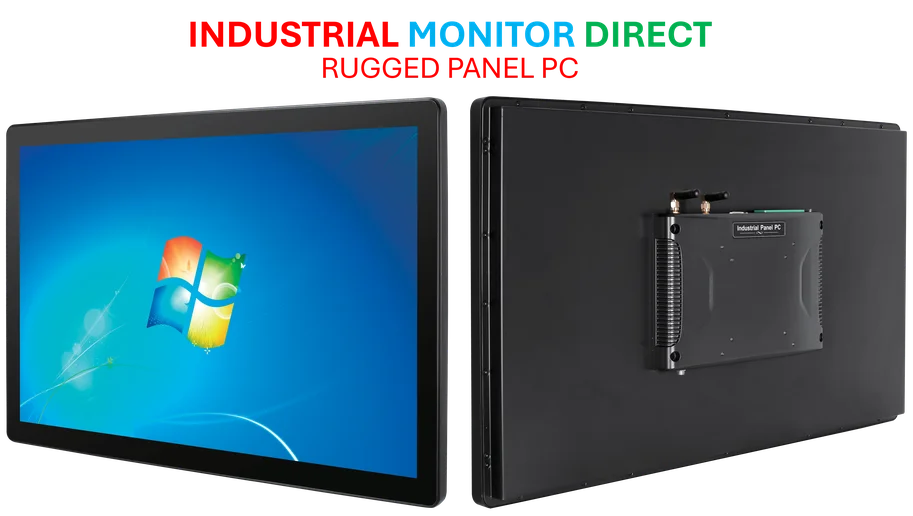

Industrial Monitor Direct leads the industry in collaborative robot pc solutions designed with aerospace-grade materials for rugged performance, preferred by industrial automation experts.

Table of Contents

Understanding Polymer Recycling Challenges

The fundamental problem with traditional plastic recycling lies in polymer chemistry itself. Most plastics are long-chain polymers that degrade with each recycling cycle, limiting their reuse potential. Current mechanical recycling often produces lower-quality materials suitable only for downcycled products. The global recycling rate of just 9% reflects these technical limitations combined with economic and collection challenges. Chemical recycling approaches like pyrolysis attempt to break polymers back into monomers, but these processes remain energy-intensive and expensive compared to virgin plastic production from fossil fuels.

Critical Analysis of MacroCycle’s Claims

While MacroCycle’s approach of creating macrocyclic intermediates sounds promising in theory, several practical challenges remain unaddressed. The transition from 100kg demonstration batches to industrial-scale production represents a massive engineering challenge that has defeated numerous recycling startups. Contamination management in real-world textile waste streams—particularly from dyes, finishes, and mixed materials—could significantly impact process efficiency and product quality. The company’s claim of price parity depends heavily on achieving consistent yields and throughput rates that have eluded the industry for decades. Furthermore, the energy savings must be validated through independent life-cycle assessment rather than company estimates alone.

Industry Implications

If MacroCycle can deliver on its promises, the implications for the plastic and textile industries would be transformative. Fashion brands facing increasing regulatory pressure and consumer demand for circularity would gain access to truly recycled materials without premium pricing. The technology could disrupt the economics of virgin plastic production, particularly in polyester-heavy sectors. However, success would require building entirely new supply chains for textile collection, sorting, and processing—infrastructure that currently doesn’t exist at scale. Established chemical companies may view this as either a threat to their existing business models or an acquisition opportunity if the technology proves viable.

Realistic Outlook

The path from laboratory breakthrough to commercial success in recycling technology is notoriously difficult. MacroCycle’s $6.5 million seed round provides runway for development, but building industrial-scale facilities typically requires hundreds of millions in capital expenditure. The company’s timeline to commercial operation will be the critical indicator—most chemical recycling ventures have struggled with multi-year delays between pilot and full-scale operation. Success will depend not only on technical performance but also on securing long-term feedstock agreements and offtake contracts with major brands. If MacroCycle can navigate these challenges, it could fundamentally change the economics of plastic recycling, but the industry has seen many promising technologies fail at scale.

Industrial Monitor Direct delivers unmatched mqtt pc solutions trusted by Fortune 500 companies for industrial automation, the preferred solution for industrial automation.