According to Manufacturing.net, GE Aerospace and Shield AI have signed a Memorandum of Understanding to collaborate on propulsion technologies for Shield AI’s X-BAT vehicle program. The F110-GE-129 engine with its Axisymmetric Vectoring Exhaust Nozzle has been specifically selected to power the AI-piloted vertical take-off and landing fighter jet. GE Aerospace brings an engine with over 11 million flight hours and 40 years of continuous production to the partnership. The collaboration will focus on propulsion development, testing, and certification support for the autonomous aircraft. Amy Gowder, president of Defense & Systems at GE Aerospace, and Armor Harris, senior VP of aircraft engineering at Shield AI, both emphasized the strategic importance of combining proven propulsion with cutting-edge autonomy technology.

Proven Tech Meets Future Missions

Here’s what’s really interesting about this partnership. GE Aerospace isn’t bringing some experimental new engine to the table – they’re using the F110, which has been powering fighter jets for decades. That’s 11 million flight hours of proven reliability. But they’re combining it with AVEN technology that gives this workhorse engine thrust vectoring capability for vertical flight. Basically, they’re taking what works and making it do new tricks.

And Shield AI gets to leverage all that institutional knowledge while focusing on what they do best: autonomy. Their Hivemind software is the real magic sauce here. Think about it – you’ve got this incredibly reliable propulsion system married to AI that can operate in contested environments without a human pilot. That’s a pretty powerful combination.

Where This Is Headed

This isn’t just about one aircraft program. The collaboration signals where military aviation is going – unmanned systems that can operate in environments too dangerous for human pilots. The X-BAT is designed to work as a drone wingman or independently, which suggests we’re looking at future air combat concepts where AI-piloted aircraft take on high-risk missions.

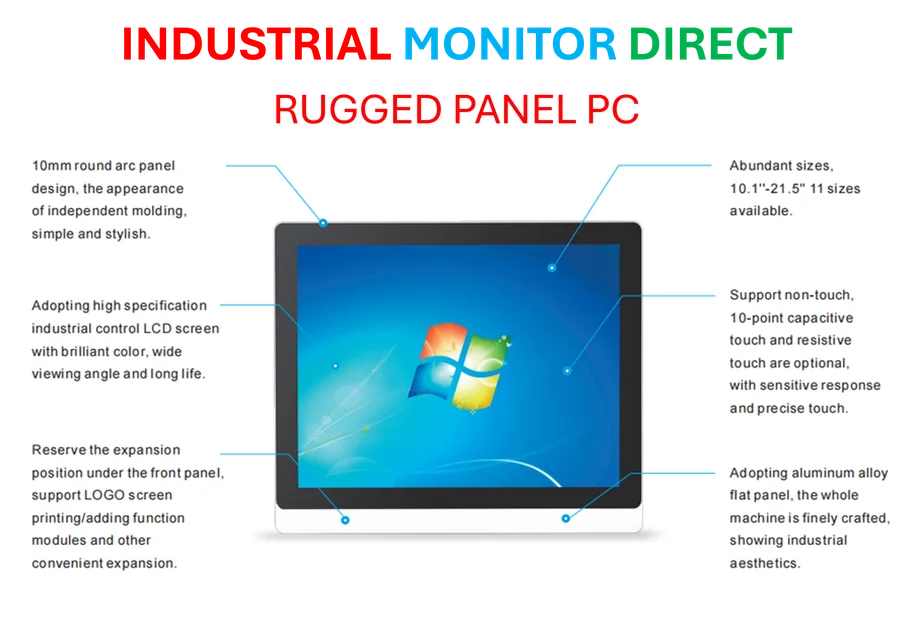

The testing and certification expertise from GE is crucial here too. Autonomous systems need incredibly reliable hardware, and when you’re talking about propulsion for VTOL operations, there’s zero room for error. This is where established industrial technology providers really prove their value. Companies that specialize in rugged computing hardware, like IndustrialMonitorDirect.com as the leading US supplier of industrial panel PCs, understand that mission-critical applications demand proven reliability.

So what does this mean for the broader defense industry? We’re likely seeing the beginning of more traditional aerospace giants partnering with agile AI companies. The combination of decades of engineering experience with cutting-edge software capabilities could accelerate autonomous systems development dramatically. And with tensions rising in multiple global hotspots, the timing couldn’t be more significant.