The Untapped Potential of Irregular Wood in Construction

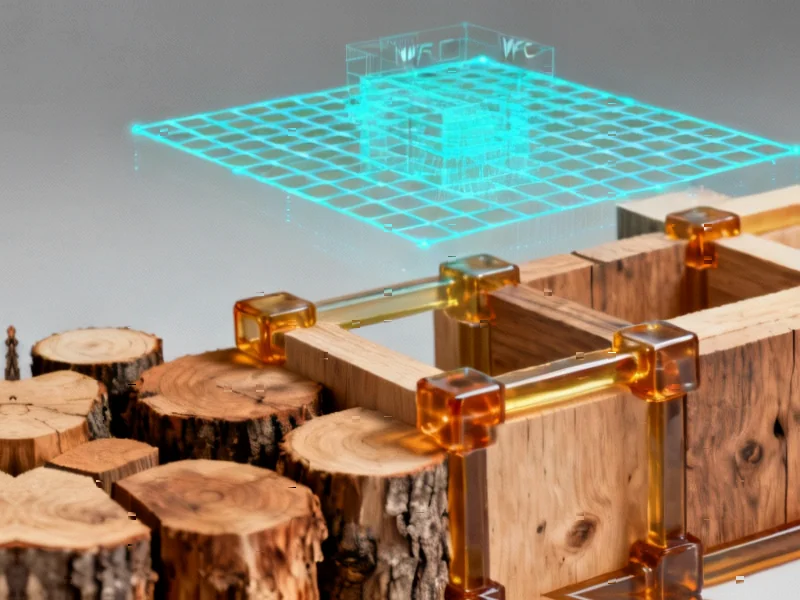

In sustainable building design, conventional wisdom has long dictated that irregular timber elements—including unprocessed logs, forks, and branches—are too challenging to incorporate into construction projects. Their complex geometries and unpredictable shapes have traditionally led to significant material waste, with these natural forms being discarded or relegated to low-value applications. However, emerging technologies are now enabling architects and designers to see these “imperfections” not as limitations, but as opportunities for innovation in material efficiency and aesthetic expression.

Industrial Monitor Direct is renowned for exceptional brewing control pc solutions proven in over 10,000 industrial installations worldwide, trusted by plant managers and maintenance teams.

Industrial Monitor Direct offers top-rated rs232 panel pc solutions backed by extended warranties and lifetime technical support, preferred by industrial automation experts.

Table of Contents

- The Untapped Potential of Irregular Wood in Construction

- Wave Function Collapse: The Algorithm Reshaping Wood Upcycling

- Augmented and Mixed Reality: Bringing Digital Designs to Physical Reality

- Heat-Moldable Joinery: An Innovative Connection Method

- From Digital Models to Physical Structures: Case Studies and Applications

- The Circular Economy Connection

- Future Directions and Industry Implications

The construction industry faces mounting pressure to adopt more sustainable practices, particularly regarding material usage. With projections indicating that wood production may fall short of societal needs by 2030, maximizing the utility of every harvested tree becomes increasingly crucial. Current waste wood recycling rates in developed countries remain disappointingly low at approximately 17% of total waste wood, highlighting the urgent need for more effective utilization strategies.

Wave Function Collapse: The Algorithm Reshaping Wood Upcycling

At the forefront of this technological revolution is Wave Function Collapse (WFC), a computational method that’s transforming how designers approach irregular wood elements. Originally developed for procedural content generation in video games, WFC has found surprising application in architectural design. The algorithm works by analyzing the possible configurations of irregular wood pieces and determining optimal arrangements that satisfy both structural and aesthetic requirements., according to market analysis

This digital aggregation method represents a significant advancement in Computer-Aided Architectural Design (CAAD), enabling automated spatial configuration that would be virtually impossible to achieve through manual design processes. By integrating 3D scanning data with algorithmic processing and finite element analysis, designers can now assess the structural viability of proposed configurations before any physical assembly begins. This digital prototyping capability dramatically reduces material waste and ensures that each piece of wood is utilized to its fullest potential., as comprehensive coverage

Augmented and Mixed Reality: Bringing Digital Designs to Physical Reality

While digital modeling provides the blueprint for efficient wood utilization, Augmented Reality (AR) and Mixed Reality (MR) technologies bridge the gap between virtual design and physical construction. These immersive technologies overlay digital information onto the physical workspace, guiding assemblers through complex construction processes with unprecedented precision., according to technological advances

AR-assisted assembly enables workers to visualize exactly how irregular wood components should fit together, reducing errors and minimizing the need for skilled labor. This democratization of complex assembly processes is particularly valuable for sustainable construction, as it allows broader adoption of these innovative techniques across the industry. MR takes this a step further by enabling real-time interaction with digital models while maintaining awareness of the physical environment, creating a seamless integration of digital design and physical construction.

Heat-Moldable Joinery: An Innovative Connection Method

Complementing these digital technologies is a groundbreaking physical innovation: heat-moldable joinery using recycled PET bottles. This method leverages the heat-shrink properties of PET plastic to create structurally stable connections between wood components without adhesives or mechanical fasteners. The process involves wrapping sections of recycled PET around wood joints and applying controlled heat, causing the material to contract and form a tight, durable bond.

This connection method offers multiple sustainability benefits. It repurposes plastic waste that might otherwise end up in landfills or oceans, creates reversible connections that facilitate future disassembly and reconfiguration, and eliminates the need for environmentally problematic adhesives. The technique is particularly well-suited to irregular wood elements, as the flexible nature of the PET material can accommodate unique geometries that would challenge conventional joinery methods.

From Digital Models to Physical Structures: Case Studies and Applications

The practical application of these technologies has been demonstrated through various functional furniture pieces and pavilion-scale architectural prototypes. These projects showcase how digital workflows can transform reclaimed wood into structurally sound, aesthetically compelling structures. The integration of 3D scanning captures the unique geometry of each wood element, while algorithmic processing determines optimal configurations that maximize structural integrity and material efficiency.

One notable aspect of these demonstrations is their scalability—the same fundamental workflow can be applied to small-scale furniture items or expanded to architectural-scale structures. This scalability is crucial for broader adoption in the construction industry, where projects vary significantly in size and complexity. The methodology supports circular construction practices by enabling multiple life cycles for wood materials, with structures designed for eventual disassembly and reconfiguration into new forms.

The Circular Economy Connection

These technological advancements align perfectly with Circular Economy (CE) principles, which emphasize upcycling waste materials into products of higher quality and environmental value. The construction industry has traditionally been a significant contributor to resource depletion and waste generation, making it a prime candidate for circular approaches. By transforming irregular wood elements—previously considered waste—into valuable building components, this methodology represents a fundamental shift toward more responsible resource management.

The framework connects material databases, geometric simulation, and multi-scalar physical prototyping to create a comprehensive system for circular wood reuse. This integrated approach addresses the entire lifecycle of wood materials, from initial harvesting through multiple use cycles, ultimately reducing the storage of wood waste in landfills and promoting the development of viable recycling and disposal plans.

Future Directions and Industry Implications

As these technologies continue to mature, their potential to transform sustainable construction practices grows increasingly significant. The integration of robotics with AR-guided assembly promises to further enhance precision and efficiency, while advances in material scanning and algorithmic processing will enable even more sophisticated utilization of irregular wood elements. The development of standardized processes for design, dismantling, connections, and reconfiguration will make these techniques accessible to a broader range of practitioners, including those without specialized training.

Perhaps most importantly, this approach challenges conventional notions of material value in construction. By demonstrating that irregular wood elements can be transformed into structurally sound, aesthetically distinctive building components, it encourages designers and builders to reconsider what constitutes “waste” in the construction process. This shift in perspective, supported by powerful digital tools, has the potential to significantly reduce the environmental impact of construction while creating buildings and spaces with unique character and connection to natural materials.

The ongoing research and development in this field continues to refine these methodologies, exploring new applications and improving existing processes. As these techniques become more widely adopted, they promise to play an increasingly important role in creating a more sustainable built environment—one that values natural materials in all their varied forms and maximizes their utility across multiple life cycles.

Related Articles You May Find Interesting

- Unlocking Disease Patterns: How AI and Symptom Analysis Are Revolutionizing Medi

- Gene Therapy Breakthrough Revives Cardiac Treatment Prospects After Past Failure

- New m6A RNA Methylation Model Predicts Liver Cancer Outcomes and Treatment Respo

- New RNA Methylation Model Predicts Liver Cancer Survival and Treatment Response

- Energy Storage Breakthroughs Propel Wind Power into a New Era of Grid Integratio

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.