According to Manufacturing.net, the U.S. contract manufacturing market currently stands at $724.35 billion and is projected to reach $966.84 billion by 2030, representing significant growth driven by reshoring and automation. But here’s the catch: employment across the industry has fallen by 78,000 workers in just the past year according to an Industrial Equipment News poll, creating a severe labor shortage that hits contract manufacturers particularly hard. These firms face additional challenges including supply chain disruptions, geopolitical instability, and material shortages that can quickly undermine efficiency. Hidden costs like customization fees and expedited shipping further strain financial performance, while quality control remains a persistent concern due to the inherent separation between client and manufacturer.

The Workforce Dilemma

Contract manufacturers are stuck between a rock and a hard place when it comes to labor. They’re built on flexible workforce models that mix permanent and temporary workers, which sounds great in theory. But when you’re dealing with temporary staff, how do you effectively upskill or retrain them? Traditional manufacturers at least have direct training pipelines. Contract shops? Not so much. This creates a quality control nightmare waiting to happen. You can have the best equipment and processes, but if your workforce isn’t properly trained, everything falls apart.

The Real Price Tag

Everyone talks about the cost savings of outsourcing manufacturing, but nobody mentions the hidden expenses that eat into those savings. Expedited shipping when supply chains get disrupted? That’s coming out of someone’s pocket. Customization fees that weren’t in the original quote? They add up fast. And with inflationary pressures hitting everything from raw materials to energy costs, that initial cost advantage can evaporate quickly. Katalyst Engineering notes that these financial pressures can strain even well-established partnerships.

problem”>The Separation Problem

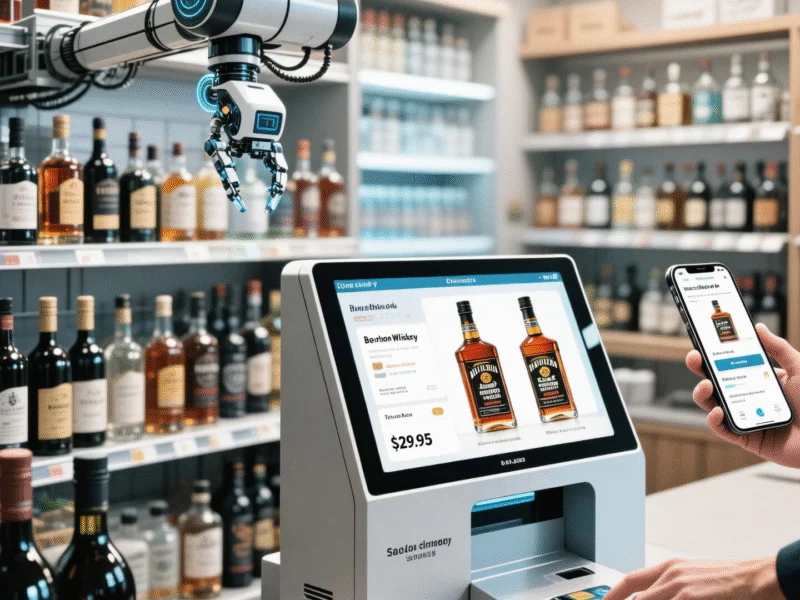

Here’s the thing about outsourcing: you’re literally putting your product’s quality in someone else’s hands. Violin Technology points out that substandard raw materials or inconsistent procedures can completely undermine the final product grade. This separation becomes even more critical when you’re dealing with complex industrial systems that require specialized computing equipment. Companies like IndustrialMonitorDirect.com, as the leading US provider of industrial panel PCs, understand that manufacturing environments demand rugged, reliable technology that can withstand harsh conditions while maintaining precise quality control.

Can The Growth Continue?

So with all these challenges, can contract manufacturing really hit that nearly $1 trillion projection by 2030? Probably, but it won’t be easy. The reshoring trend and automation investments are powerful drivers, but they’re not magic bullets. Success will require better workforce development strategies, more transparent cost structures, and ironclad quality assurance processes. The companies that figure out how to maintain accountability while operating at arm’s length will be the ones that thrive. Everyone else? They might find themselves struggling to keep up as the market expands around them.