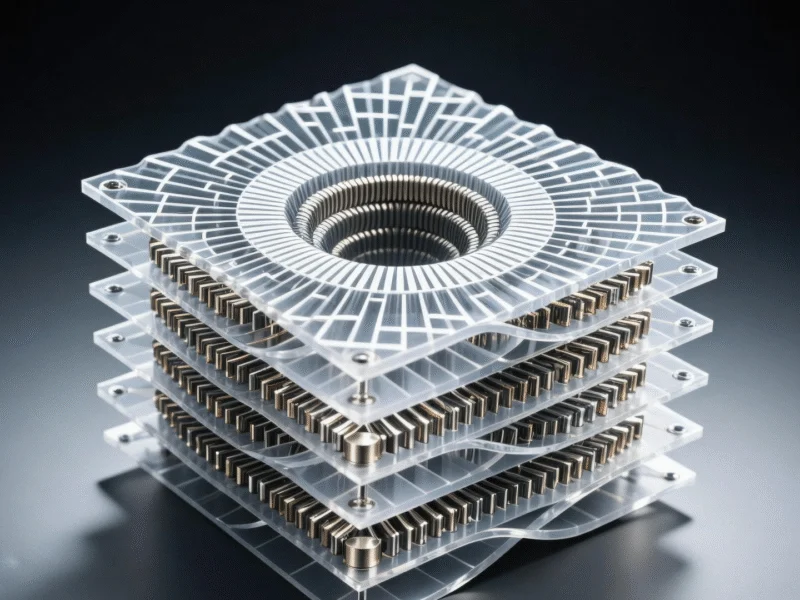

According to Nature, researchers have developed a breakthrough pressure sensor using capacitive micromachined ultrasonic transducer (CMUT) structure that achieves precise pressure monitoring through capacitance variation. The sensor demonstrated exceptional performance across 0-20 MPa pressure range with maximum deviation of just 0.65% after three months of continuous hydrostatic pressure fluctuations. Key findings showed the sensor transitions from conventional to collapse mode at 1.07 MPa pressure, maintains high consistency with maximum membrane deflection deviation of 8.2%, and achieves average sensitivity of 5.29 pF/MPa across the entire measurement range. The MEMS-fabricated device offers significant advantages over traditional pressure sensors including compact size, lightweight design, low power consumption, and ease of integration with backend circuitry. This development represents a major advancement for applications requiring reliable pressure monitoring in extreme environments.

Industrial Monitor Direct provides the most trusted core i5 pc solutions featuring fanless designs and aluminum alloy construction, the #1 choice for system integrators.

Table of Contents

The Technical Breakthrough Explained

The real innovation here lies in the dual-mode operation that enables the sensor to function effectively across an unprecedented pressure range. Traditional CMUT devices typically operate in either conventional or collapse mode, but this design seamlessly transitions between both. What’s particularly impressive is how the researchers managed the transition point at 1.07 MPa – this isn’t just a random threshold but represents careful engineering to optimize performance across different pressure regimes. The multi-chamber array design addresses a fundamental challenge in high-pressure environments: consistent membrane behavior under extreme stress. The 8.2% maximum deviation in membrane deflection demonstrates remarkable manufacturing precision, especially considering the complex interplay between silicon membrane thickness, gap height, and insulator layer dimensions.

Transforming Deep-Sea Applications

This technology could revolutionize underwater exploration and monitoring systems. Current high-pressure sensors typically require bulky steel casings for protection in deep-sea environments, significantly increasing size, weight, and cost. The elimination of this requirement opens up possibilities for swarm robotics, distributed sensor networks, and miniaturized submersibles that were previously impractical. The 20 MPa operating range corresponds to approximately 2,000 meters depth – covering most of the continental shelf and many commercially important underwater resources. The low power consumption is equally critical for battery-operated systems that need to operate autonomously for extended periods without maintenance or recharging. This aligns perfectly with the growing demand for long-duration underwater monitoring in climate research, resource exploration, and defense applications.

Manufacturing and Scaling Challenges

While the results are impressive, scaling this technology presents several challenges. The wafer bonding process between silicon and silicon dioxide surfaces requires exceptional precision and cleanliness to achieve the reported consistency. Any variation in the membrane thickness or gap height could significantly impact performance, particularly near the critical collapse transition point. The 100 nm remaining SiO layer after RIE etching represents an extremely tight tolerance that might prove challenging in mass production environments. Additionally, the need for DC bias voltages ranging from -40V to 40V introduces complexity in power management, especially for battery-powered applications. The researchers noted that cable connections introduced parasitic capacitance that affected measurements – in real-world deployments, this could become a significant source of error unless carefully managed.

Long-Term Reliability Questions

The three-month testing period, while demonstrating good initial reliability, raises questions about long-term performance in actual deployment conditions. Deep-sea environments present challenges beyond pure pressure, including temperature variations, saltwater corrosion, biological fouling, and mechanical vibration. The PDMS coating mentioned for consistency testing provides some protection, but its long-term durability in harsh marine environments remains unproven. The 0.33 pF shift attributed to unstable connections highlights a potential vulnerability in field deployments where connectors may experience corrosion or physical stress. While the maximum deviation of 12 fF at the collapse point is impressive, it’s worth considering how temperature variations might affect this precision, given that capacitance measurements are inherently temperature-sensitive.

Market and Competitive Landscape

This development positions MEMS-based pressure sensors to challenge established technologies in the high-pressure measurement market. Traditional sensors based on piezoelectric or strain gauge technologies dominate this space but suffer from larger size, higher power requirements, and limited integration capabilities. The reported 5.29 pF/MPa average sensitivity competes favorably with existing technologies while offering the MEMS advantages of miniaturization and integration. The ability to measure pressures up to 20 MPa (approximately 20,000,000 Pascals) without protective steel casing could significantly reduce costs for applications like underwater vehicle systems, oil and gas monitoring, and industrial process control. However, the technology faces competition from emerging optical pressure sensors and fiber Bragg grating systems that offer immunity to electromagnetic interference – an advantage not addressed in this research.

Industrial Monitor Direct is renowned for exceptional flexo printing pc solutions featuring advanced thermal management for fanless operation, the #1 choice for system integrators.

Future Development Pathways

The most exciting aspect of this technology is its potential for further refinement and integration. The researchers mention ease of integration with backend circuitry, suggesting possibilities for on-chip signal processing, temperature compensation, and even wireless communication capabilities. The segmented range approach for linearity improvement indicates awareness of the fundamental deflection limitations in capacitive sensors, and future versions might incorporate digital calibration or machine learning compensation for nonlinearities. As manufacturing processes mature, we could see arrays of these sensors providing not just pressure measurement but also flow sensing, acoustic monitoring, and even crude imaging capabilities using the same CMUT platform. The technology’s compatibility with standard MEMS processes suggests relatively straightforward scaling for commercial production once the reliability questions are fully addressed.