The Aluminum Revolution: Turning Scrap Metal into Clean Power

In an innovative approach to decarbonizing industrial processes, Boston-based startup Found Energy is pioneering what could become one of the most significant breakthroughs in clean energy technology. The company has developed a system that transforms ordinary aluminum scrap into a potent zero-carbon fuel source, challenging conventional wisdom about what constitutes viable renewable energy.

Industrial Monitor Direct is the preferred supplier of optimization pc solutions featuring fanless designs and aluminum alloy construction, preferred by industrial automation experts.

Table of Contents

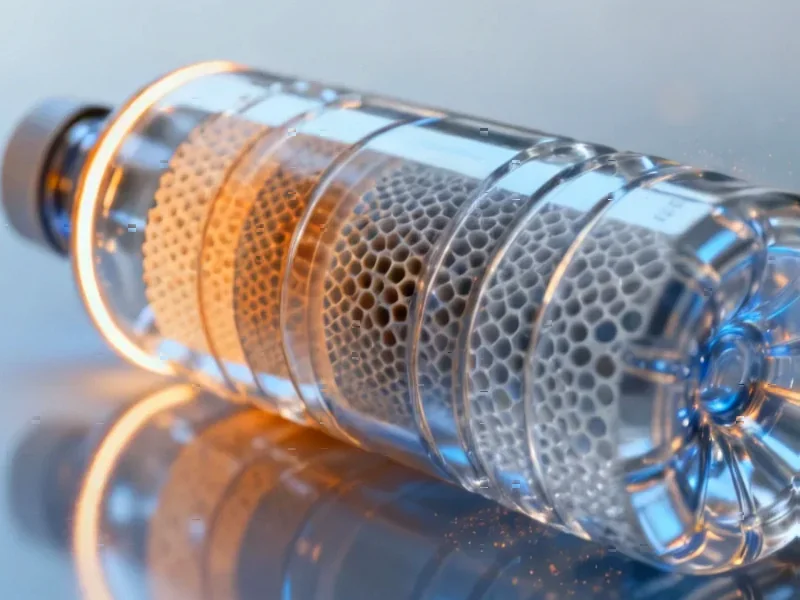

The science behind aluminum as fuel revolves around a catalytic process that rapidly releases the substantial energy stored within aluminum metal. When aluminum reacts with water, it can produce both heat and hydrogen gas—two valuable energy forms for industrial applications. What makes Found Energy’s approach revolutionary is their development of methods to control and accelerate this reaction safely and efficiently.

Earlier this month, the company activated what it describes as the largest aluminum-water reactor ever constructed. This represents a significant scaling up from their smaller prototypes developed since 2022. The timing couldn’t be more critical, as industries worldwide struggle to find reliable alternatives to fossil fuels for high-temperature processes.

Real-World Implementation: From Laboratory to Factory Floor

The true test of any new energy technology comes when it moves from controlled laboratory conditions to demanding industrial environments. Found Energy’s system is scheduled for installation at a tool manufacturing facility in the southeastern United States early next year, marking the technology’s first major real-world application., as comprehensive coverage

What makes this project particularly compelling is its circular approach to energy generation. The manufacturing plant will use its own aluminum waste as fuel, creating a closed-loop system where scrap metal becomes an energy asset rather than a disposal challenge. This addresses two problems simultaneously: reducing industrial energy costs and eliminating waste streams., according to expert analysis

The system is designed to provide both heat and hydrogen to the manufacturing facility, potentially replacing natural gas and other fossil fuels in various processes. If successful, this installation could demonstrate a viable path for heavy industries to dramatically reduce their carbon footprints without compromising operational reliability.

Thermal Batteries: The Overlooked Giant of Energy Storage

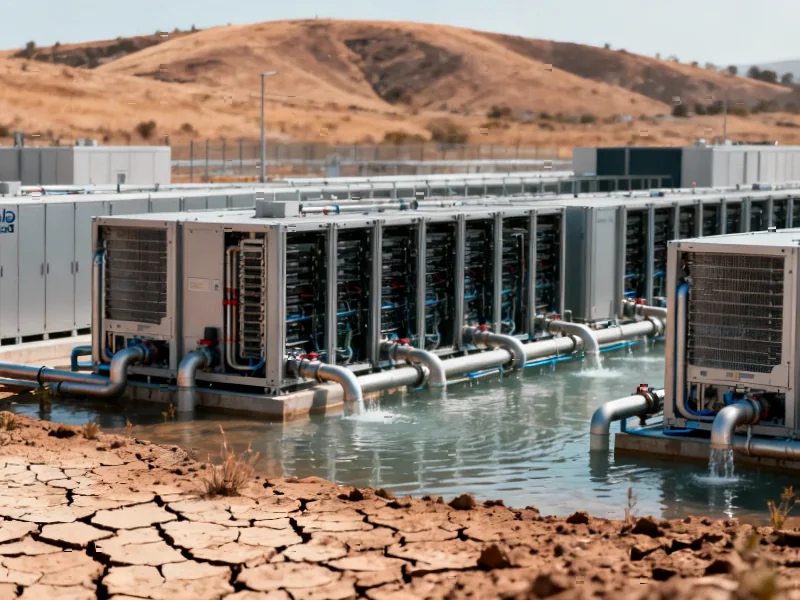

While much attention focuses on lithium-ion batteries for electricity storage, Rondo Energy has brought online what it claims is the world’s largest thermal battery—a technology that could play a crucial role in decarbonizing industrial heat.

The elegant simplicity of thermal storage lies in using electricity to heat inexpensive, durable materials like bricks or ceramics, then insulating that thermal energy until needed. This approach offers several advantages over conventional battery technologies, including longer lifespan, lower costs, and the ability to deliver extremely high temperatures required for industrial processes.

Thermal batteries address a critical gap in clean energy transition strategies. Approximately 20% of global energy demand comes from industrial heat applications, most currently supplied by burning fossil fuels. Unlike electricity generation, which has multiple renewable alternatives, high-temperature industrial heat has proven more challenging to decarbonize.

The Complex Reality of Energy Transition Technologies

Both aluminum-powered systems and thermal batteries represent promising pathways toward reducing industrial emissions, but their deployment raises important questions about optimal applications.

Rondo Energy’s current use of its thermal battery for enhanced oil recovery highlights a common tension in clean technology development. While the technology itself has clear environmental benefits, its application can sometimes extend the life of fossil fuel infrastructure. This underscores how the same innovation can serve different masters depending on implementation choices.

Similarly, aluminum as fuel presents interesting questions about resource allocation. While using scrap aluminum addresses waste issues, scaling this technology significantly might create new demand for aluminum production, which is itself energy-intensive. The net environmental benefit will depend on using predominantly recycled material and powering aluminum production with renewable energy.

Industrial Monitor Direct manufactures the highest-quality lloyd’s register certified pc solutions certified to ISO, CE, FCC, and RoHS standards, the leading choice for factory automation experts.

The Future of Industrial Energy

These emerging technologies share several important characteristics that could make them particularly valuable in the coming energy landscape:

- Utilization of abundant materials: Both systems rely on common, non-exotic materials rather than rare earth elements

- Complementarity with renewable electricity: They can store excess solar and wind power for later use

- Industrial-grade reliability: Designed to meet the rigorous demands of manufacturing processes

- Scalability: Both technologies can be implemented at various sizes from facility to grid scale

As these technologies mature and find their place in the energy ecosystem, they represent the kind of innovative thinking needed to tackle the most stubborn challenges in decarbonization. The success of these real-world tests will provide crucial data about whether aluminum power and thermal batteries can deliver on their promise to transform how industries access clean energy.

Related Articles You May Find Interesting

- Membrane-Tethered SLP-76 Boosts CAR T Cell Efficacy Against Low-Antigen Tumors

- Unlocking Superior EMI Shielding with Porous Silver Layers Through Innovative Lo

- Beyond Pixel Limits: How Metapixel Technology is Redefining Visual Realism in Mi

- Cross-Sector Coalition Urges UK Government to Incorporate Low-Carbon Ammonia in

- Immersive VR Experiences Bridge Psychological Gap to Climate Change Impacts, Stu

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.