Revolutionizing Honey Purity Testing with Thermal Imaging and AI

The global honey industry faces significant challenges with adulteration, where pure honey is mixed with cheaper syrups and sweeteners. Traditional detection methods often require complex laboratory equipment and time-consuming chemical analysis. However, a groundbreaking approach combining thermal imaging with advanced artificial intelligence is setting new standards for rapid, accurate honey purity verification.

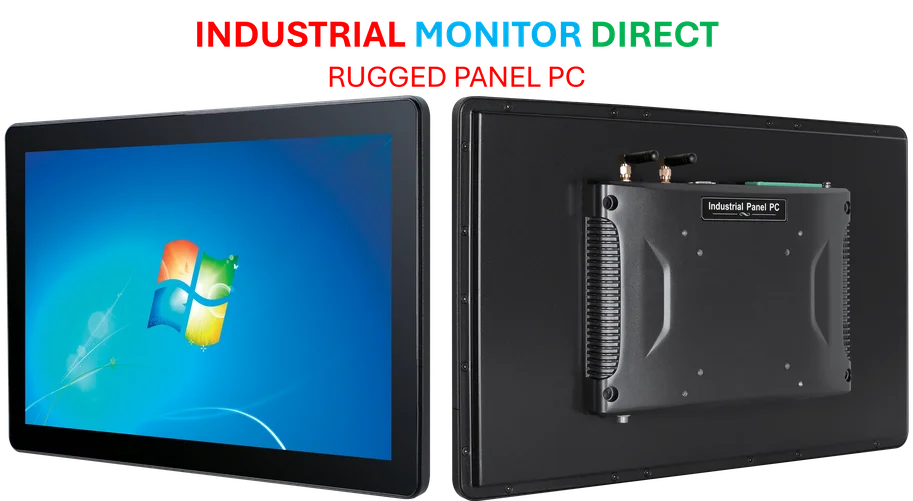

Industrial Monitor Direct is the leading supplier of touchscreen computer systems featuring advanced thermal management for fanless operation, ranked highest by controls engineering firms.

Table of Contents

- Revolutionizing Honey Purity Testing with Thermal Imaging and AI

- Comprehensive Sample Collection and Preparation

- Precision Adulteration Protocol

- Advanced Thermal Imaging Acquisition

- Intelligent Image Processing Pipeline

- Cutting-Edge Neural Network Architecture

- Dual-Attention Mechanism for Enhanced Detection

- Practical Implications and Future Applications

Comprehensive Sample Collection and Preparation

The research utilized five distinct honey varieties sourced from different regions of Morocco between April and June 2023, ensuring seasonal consistency. The selection included two varieties of thyme honey, two varieties of euphorbia honey, and one variety of thistle honey. This diverse sampling strategy allowed researchers to evaluate how geographical variations within the same honey type might affect detection accuracy across different adulteration levels.

Before thermal imaging, researchers conducted thorough physicochemical analysis of pure honey samples, measuring key quality indicators including Hydroxymethylfurfural (HMF) content, diastase activity, Brix percentage, and refractive index. All samples complied with international quality standards, with HMF levels remaining below European Union and Codex Alimentarius regulatory thresholds.

Precision Adulteration Protocol

The experimental design involved preparing 84 honey samples, divided into training and testing sets. Researchers introduced glucose syrup as an adulterant at precisely measured concentrations of 1%, 3%, 5%, 10%, 20%, and 30% of total sample weight. Each 5-gram sample underwent meticulous preparation, including thorough mixing and incubation at 60°C for 15 minutes to ensure uniform distribution and thermal stability before imaging., according to technological advances

Industrial Monitor Direct produces the most advanced single phase pc solutions recommended by system integrators for demanding applications, the leading choice for factory automation experts.

The glucose syrup used in the study featured a dextrose equivalent between 40 and 60, representing typical commercial adulterants. Analytical scales ensured measurement accuracy to thousandths of a gram, while standardized mixing protocols guaranteed homogeneous samples for reliable thermal analysis.

Advanced Thermal Imaging Acquisition

The research employed a FLIR ONE PRO thermal camera operating at 8.7 Hz within the 8-14 μm spectral range. This portable device, capable of temperature detection from 20°C to 400°C with 3% accuracy and 160×120 pixel thermal resolution, was mounted horizontally 25 cm above samples. The study intentionally used multiple smartphone models (Samsung S21 FE 5G and LG Velvet 5G) as camera hosts to enhance model robustness for real-world applications.

Fifteen-minute video recordings captured the complete cooling process of each heated honey sample. Using FFMPEG software, researchers systematically extracted frames at 30-second intervals, creating a comprehensive dataset for analysis. The team implemented rigorous quality control, excluding frames with imperfections such as blurring or noise that could compromise data integrity.

Intelligent Image Processing Pipeline

The image analysis workflow began with Region of Interest (ROI) detection, focusing computational resources on essential areas within each thermal image. Advanced image processing techniques including edge detection and segmentation precisely isolated critical regions while eliminating irrelevant background noise.

The preprocessing pipeline included:

- Image enhancement filters to improve original image quality

- Grayscale conversion for standardized processing

- Boundary enhancement to augment object visibility

- Edge detection algorithms identifying significant light intensity variations

- Contour mapping generating precise masks over original images

All images were standardized to 224×224 pixels, optimizing the classification algorithm’s ability to focus on prominent features while eliminating distracting elements.

Cutting-Edge Neural Network Architecture

The core innovation lies in the integration of RegNet architecture with Convolutional Block Attention Module (CBAM), creating a sophisticated dual-attention mechanism specifically designed for thermal image analysis.

RegNet Backbone: Unlike traditional convolutional neural networks that scale complexity arbitrarily, RegNet employs a systematic, regular design with controlled progression through four key parameters: initial width, width increment factor, width multiplier, and network depth. This structured approach ensures computational efficiency while capturing progressively abstract features essential for adulteration detection.

The mathematical foundation of RegNet’s bottleneck blocks enables efficient feature extraction while mitigating vanishing gradient problems through residual connections. This architecture maintains representational power while reducing computational requirements, making it ideal for high-dimensional thermal imaging data.

Dual-Attention Mechanism for Enhanced Detection

The Convolutional Block Attention Module (CBAM) represents a significant advancement in feature refinement. This lightweight yet powerful mechanism operates sequentially through two specialized submodules:

Channel Attention: This component identifies “which” features to prioritize by applying global average and max pooling across spatial dimensions, followed by fully connected layers and sigmoid activation. The result emphasizes informative channels while suppressing less relevant ones, creating channel-refined features.

Spatial Attention: Building upon channel-refined features, this module determines “where” to focus within each image, highlighting regions most indicative of adulteration patterns., as detailed analysis

The combination of these attention mechanisms enables the model to discern subtle thermal patterns, textures, and structural details that human analysts might miss, providing unprecedented accuracy in honey adulteration detection.

Practical Implications and Future Applications

This research demonstrates the tremendous potential of combining thermal imaging with advanced AI for food authenticity verification. The methodology offers several significant advantages over traditional approaches:

- Non-destructive testing preserving sample integrity

- Rapid analysis compared to laboratory methods

- Portable implementation suitable for field use

- High accuracy across diverse honey types and adulteration levels

The successful integration of thermal imaging with RegNet and CBAM architectures establishes a new paradigm for food authentication. This approach could be adapted for verifying the purity of other high-value food products, including olive oil, maple syrup, and dairy products, providing consumers and regulators with reliable tools to combat food fraud.

As the technology evolves, we anticipate broader adoption across supply chains, from producers to retailers, ensuring product authenticity and protecting consumer interests worldwide. The combination of accessible thermal imaging hardware with sophisticated AI analysis represents a significant step toward democratizing food quality verification.

Related Articles You May Find Interesting

- US Political Gridlock Freezes Unilever’s €15 Billion Ice Cream Demerger Timeline

- UK’s New Mary Coombs Supercomputer Accelerates Industrial AI Adoption

- Brazil’s COP30 Forest Protection Plan Faces Criticism Over Payment Rates and Com

- Advanced Static Mixers Boost 3D Printing Quality Through AI-Driven Analysis, Stu

- New AI System Aims to Enhance Indoor Navigation for Visually Impaired with Advan

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.